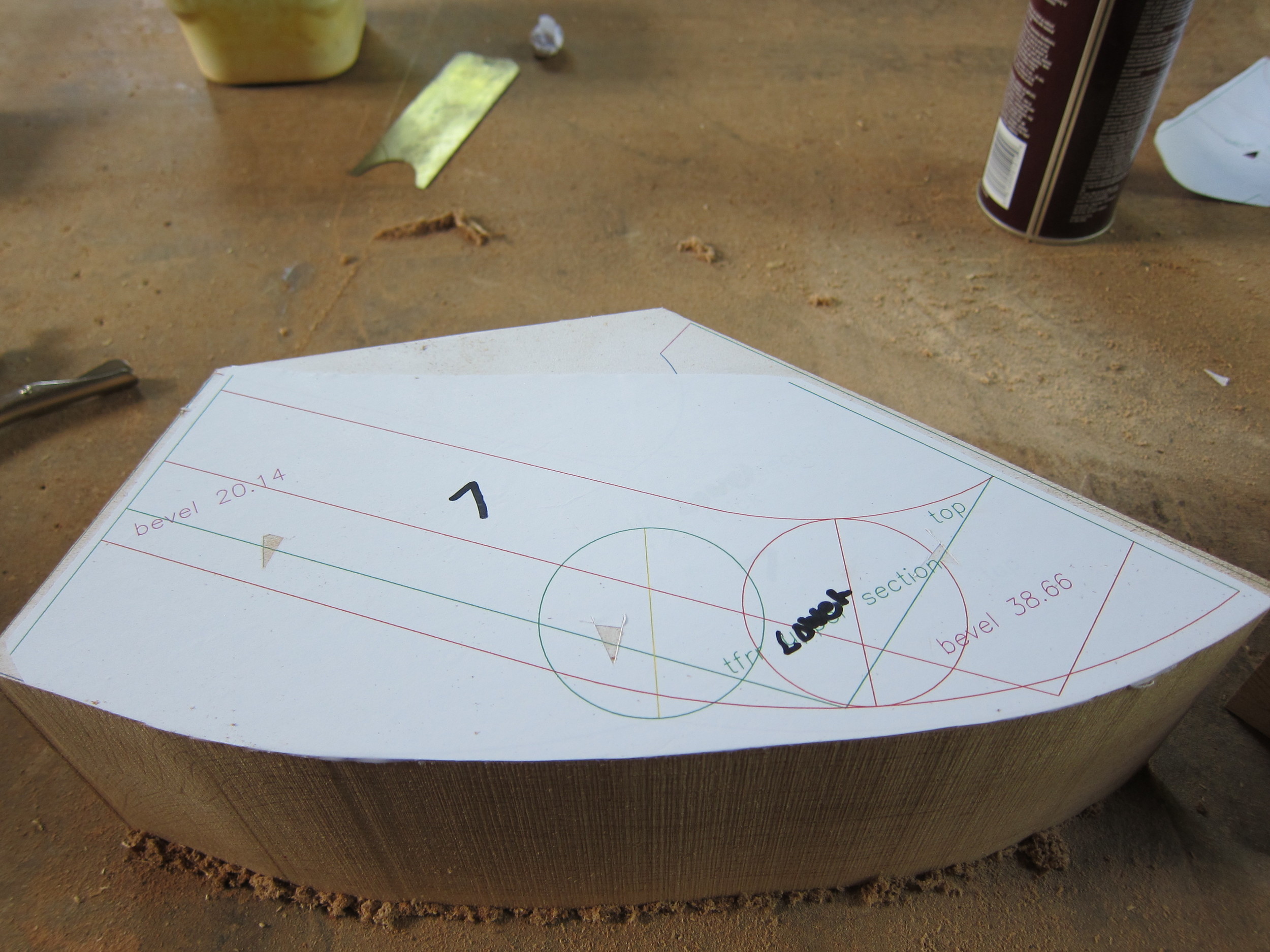

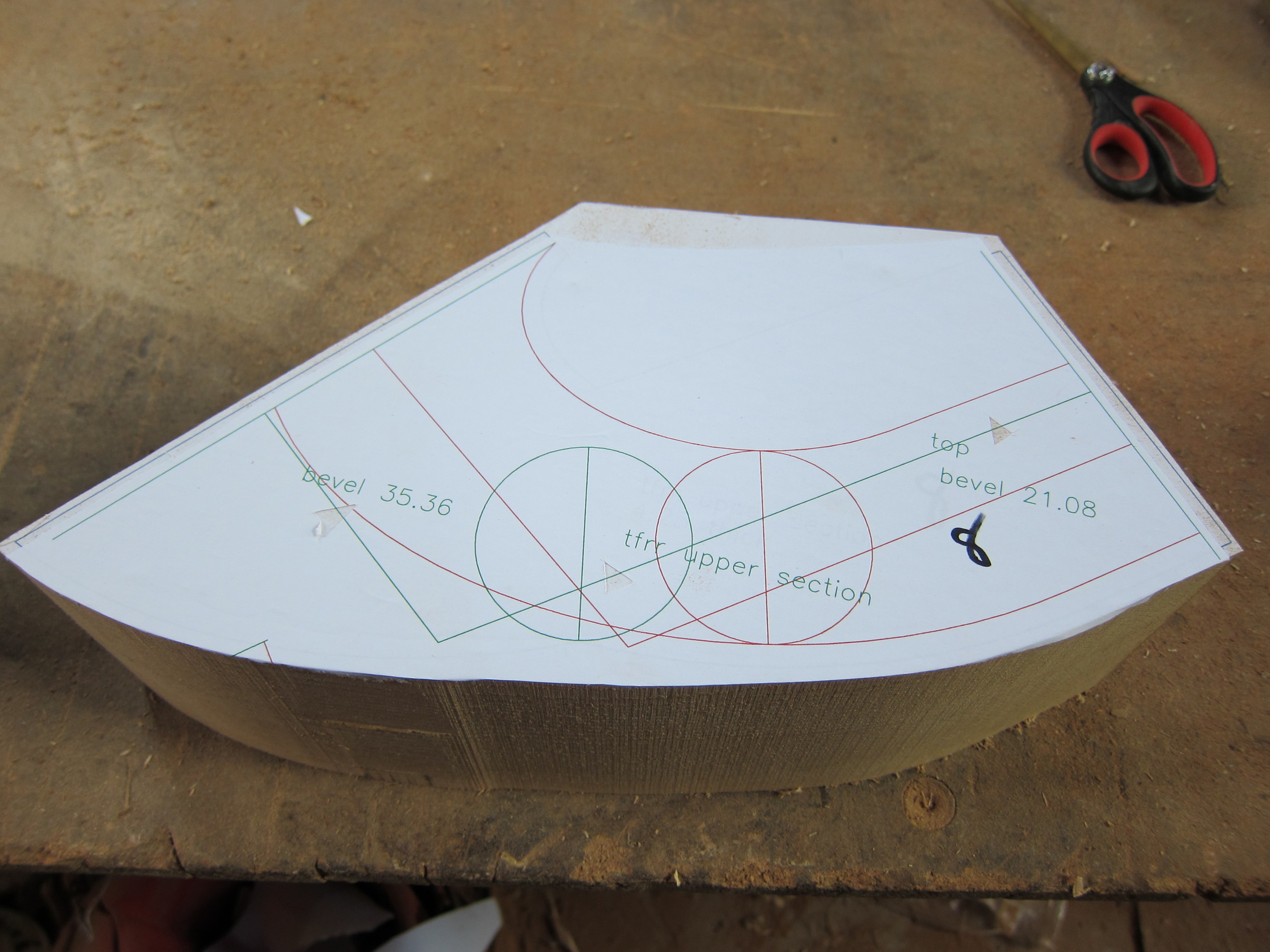

Now that I have opened myself up for praise or criticism, I would like to comment on the pictures posted, further down on this blog under "Tangent Handrailing the Process" on March 31 2015.

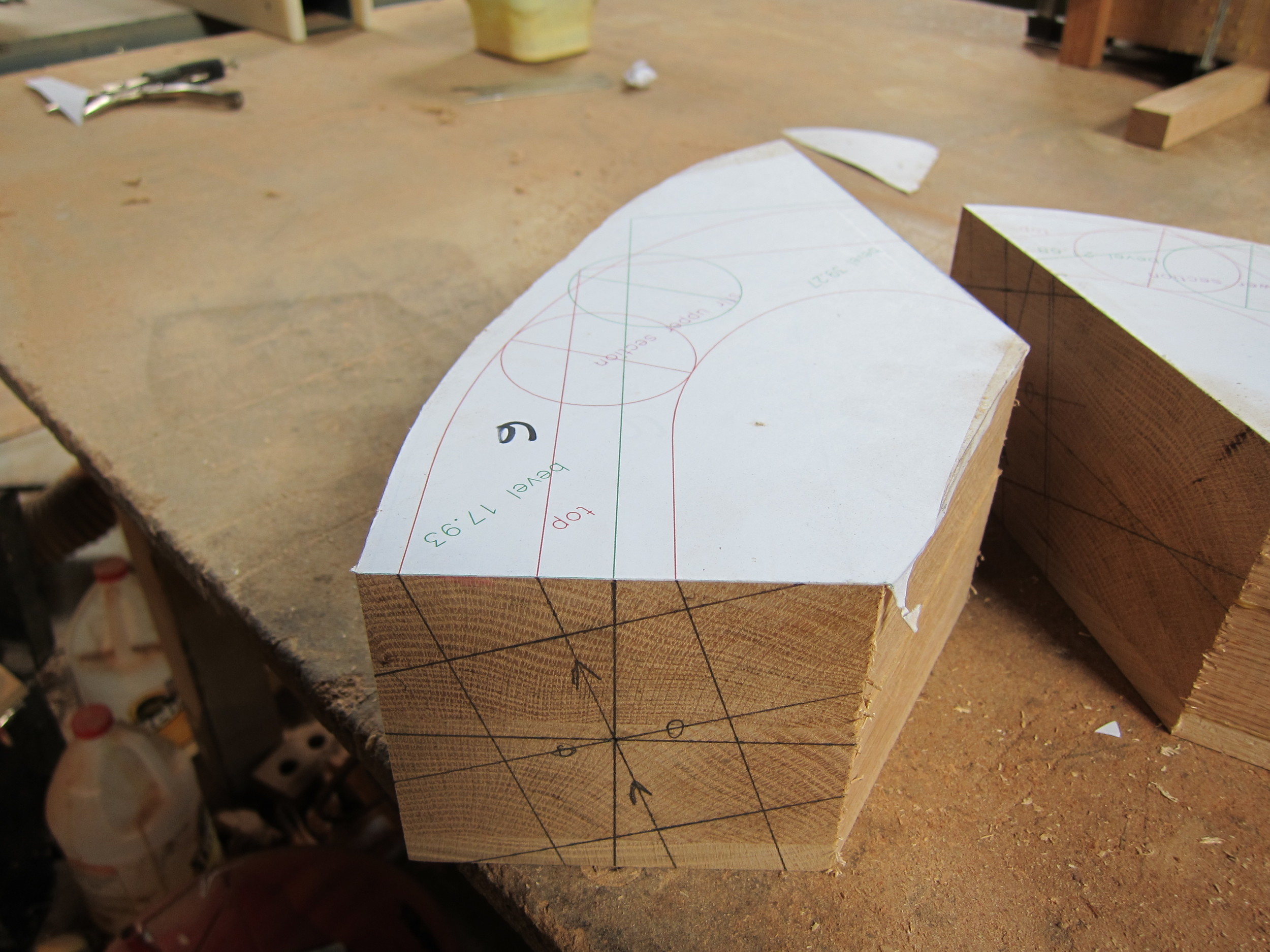

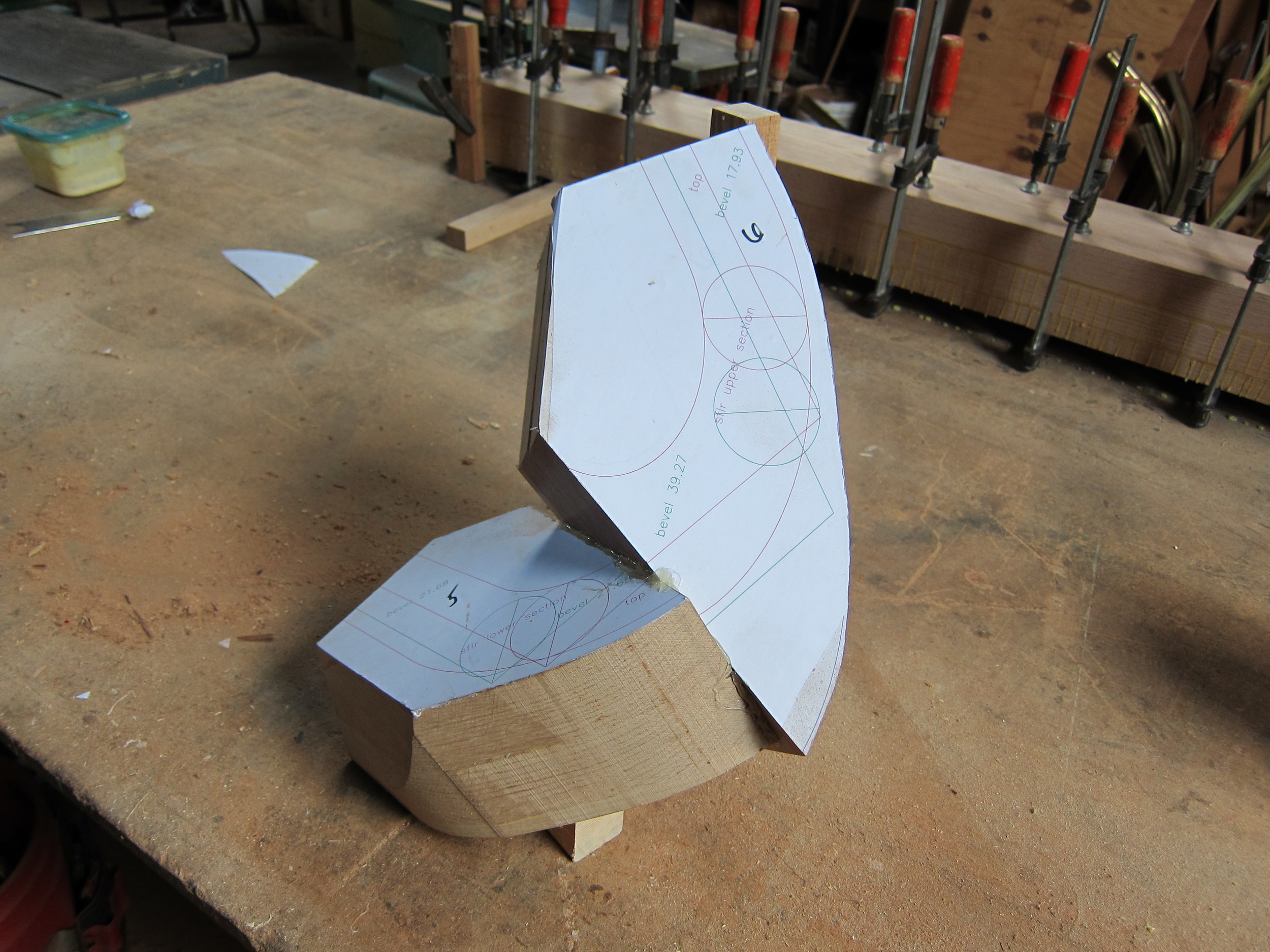

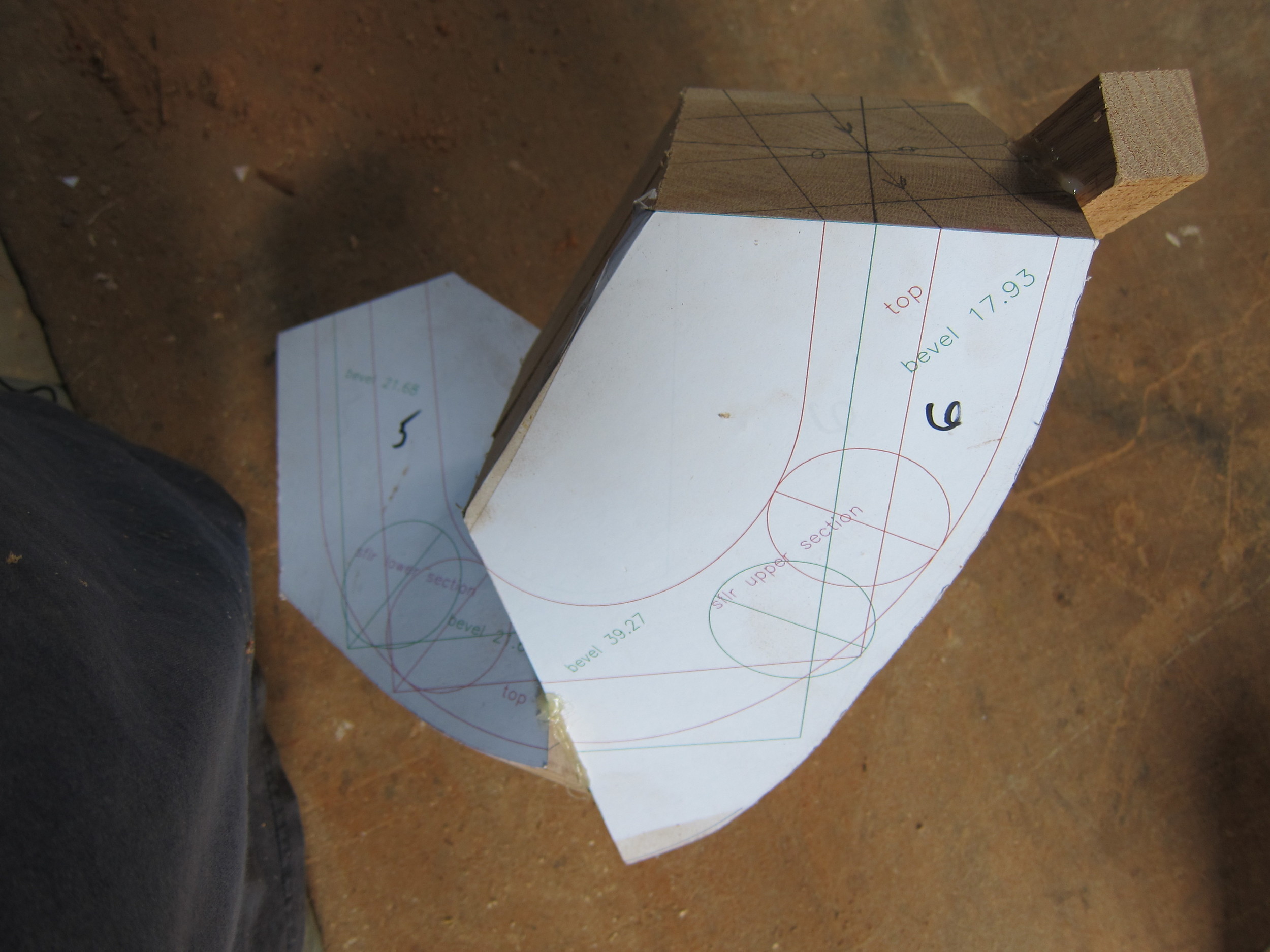

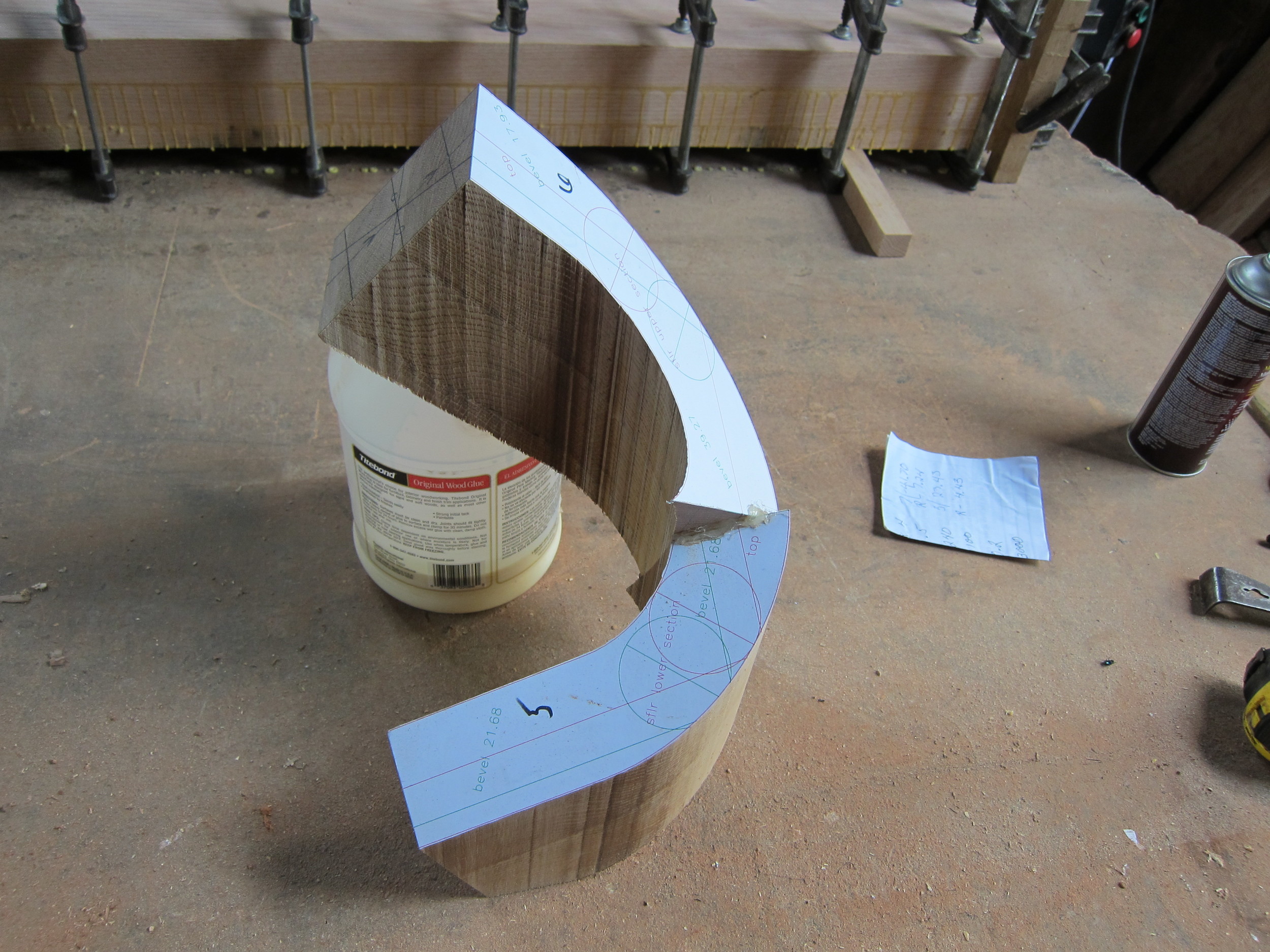

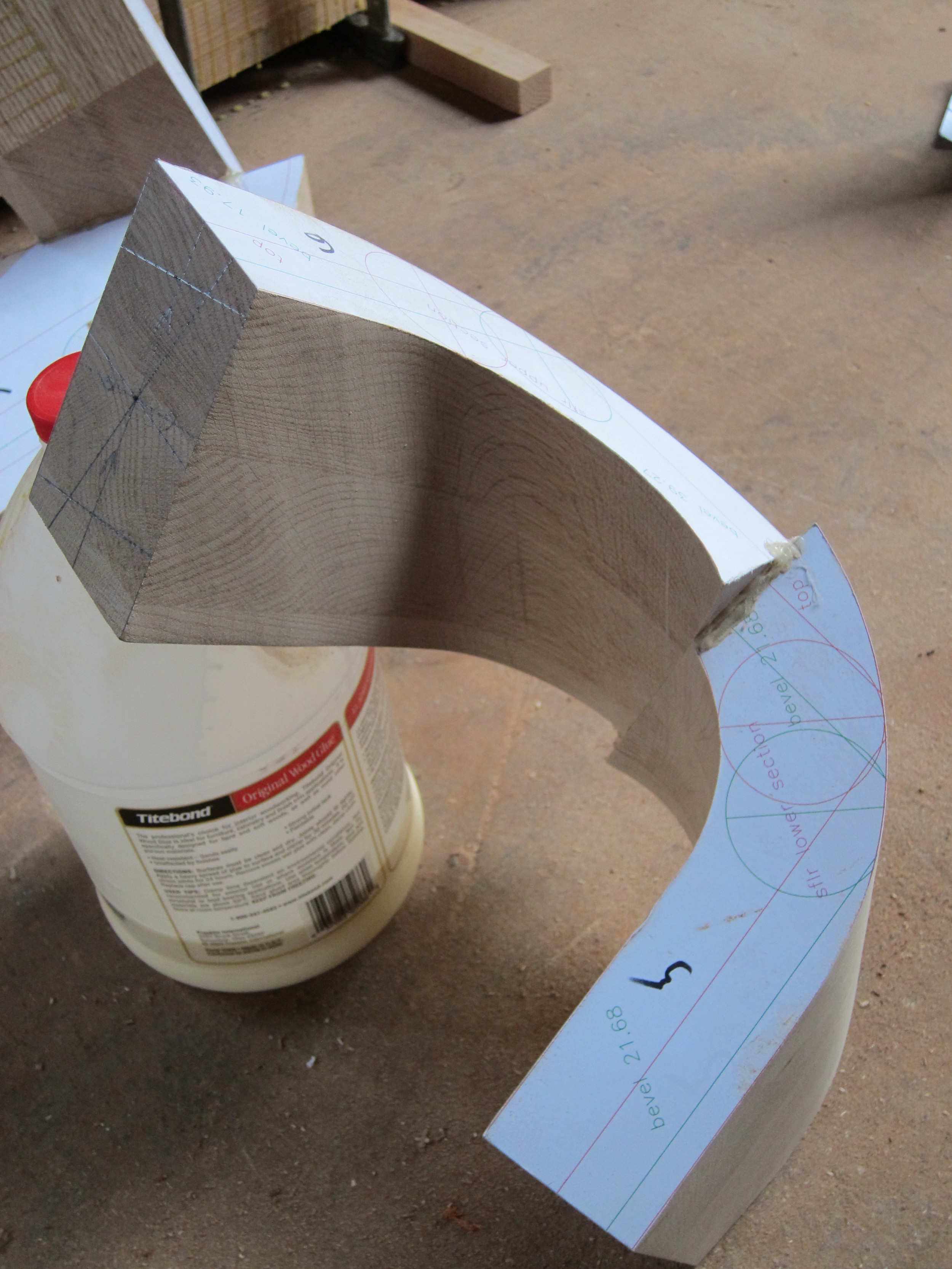

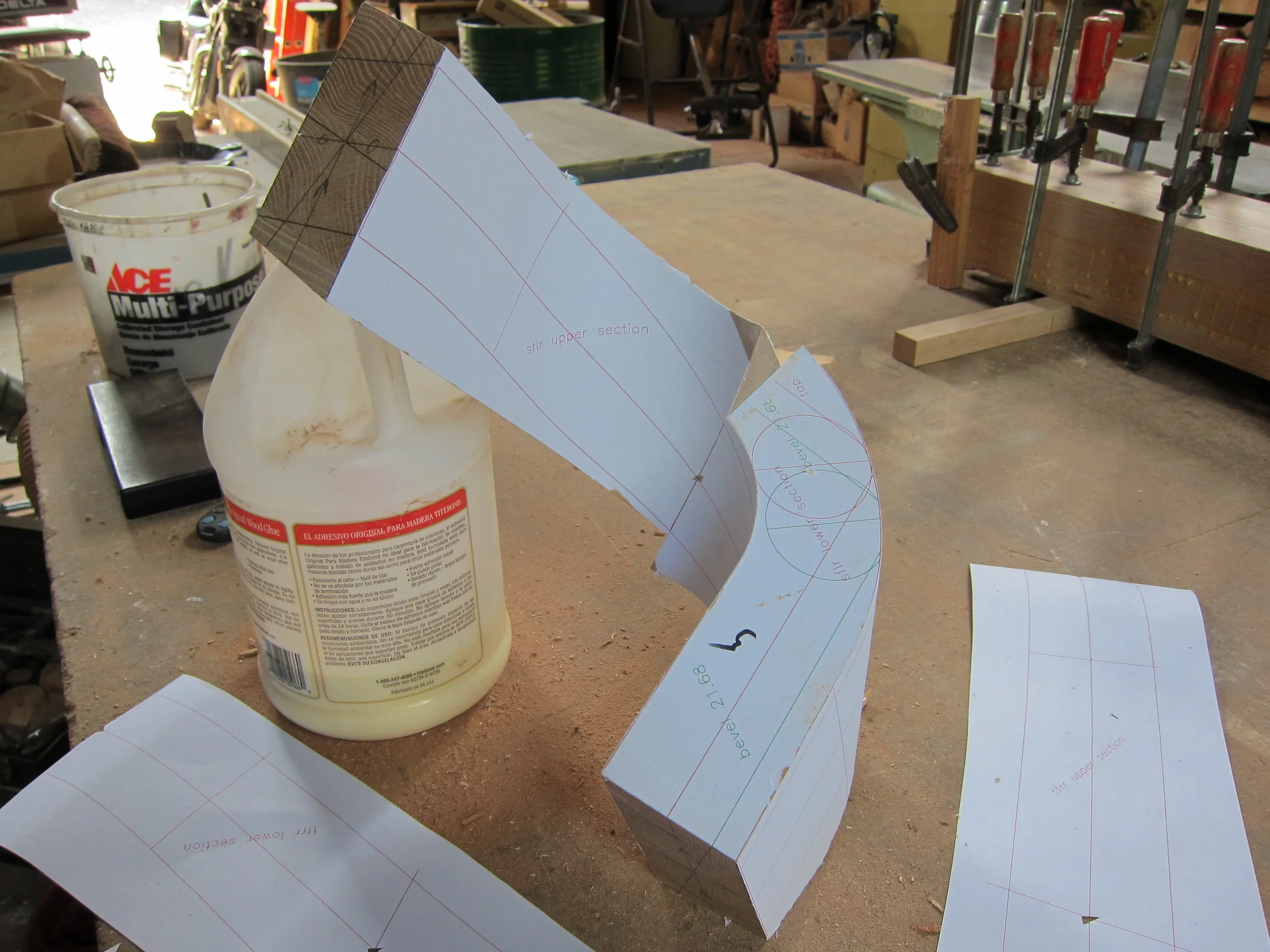

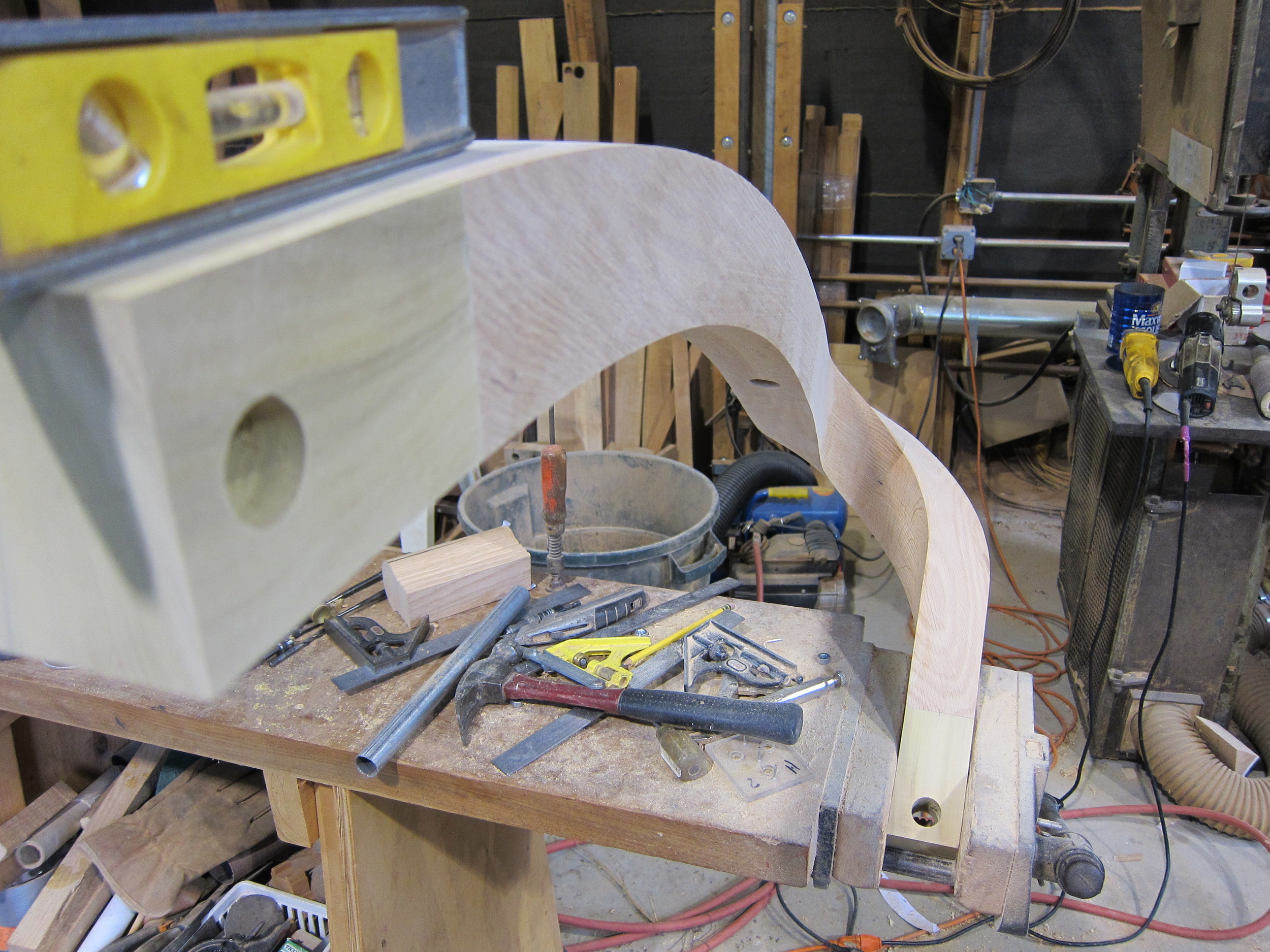

As in all things we learn as we go and along the way we make changes as we see them. These pictures were taken some time ago while exploring a way for me to achieve the best possible end result with the tools and knowledge that I had at the time. I also thought these particular pictures provided a good visual of the process I was using at the time. Yes, I used the bevel cut method and not the square cut method and yes I like the falling molds and no I don't strictly use any of these methods today. New technology has changed the way I do things today and many of the tools that I used daily, I rarely use today. My drawings have gone from 2 dimension to 3D and my tools have changed from hand feed to hand programmed. I can now do things more consistently with greater accuracy and with a higher degree of safety. Having said that, I must say that without the background in the old art of "Tangent Handrailing" I would be somewhat lost even with the new technology available today. No matter which method you use, whether you are making face molds to apply on your block or 3D drawings to program your machine, the drawing is the key to success. Both schools have there challenges. Fairing a rail by eye with hand tools can at times be easier than with a 3D drawing program. However the main reason that I upgraded my process was mostly for safety reasons. Many of the old methods are very dangerous and I was reluctant to employ anyone because of the risks but now I feel confident to keep this craft alive and do it safely.

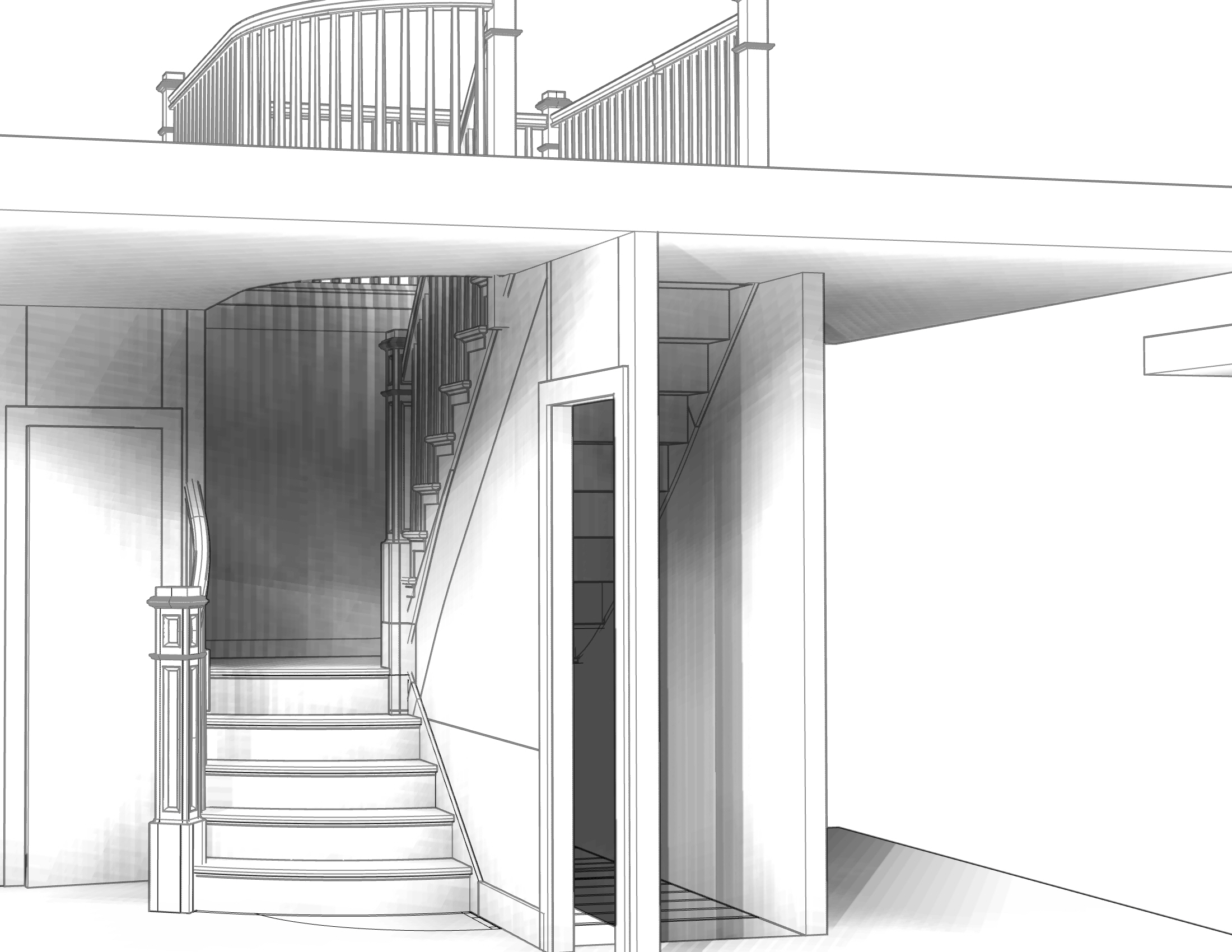

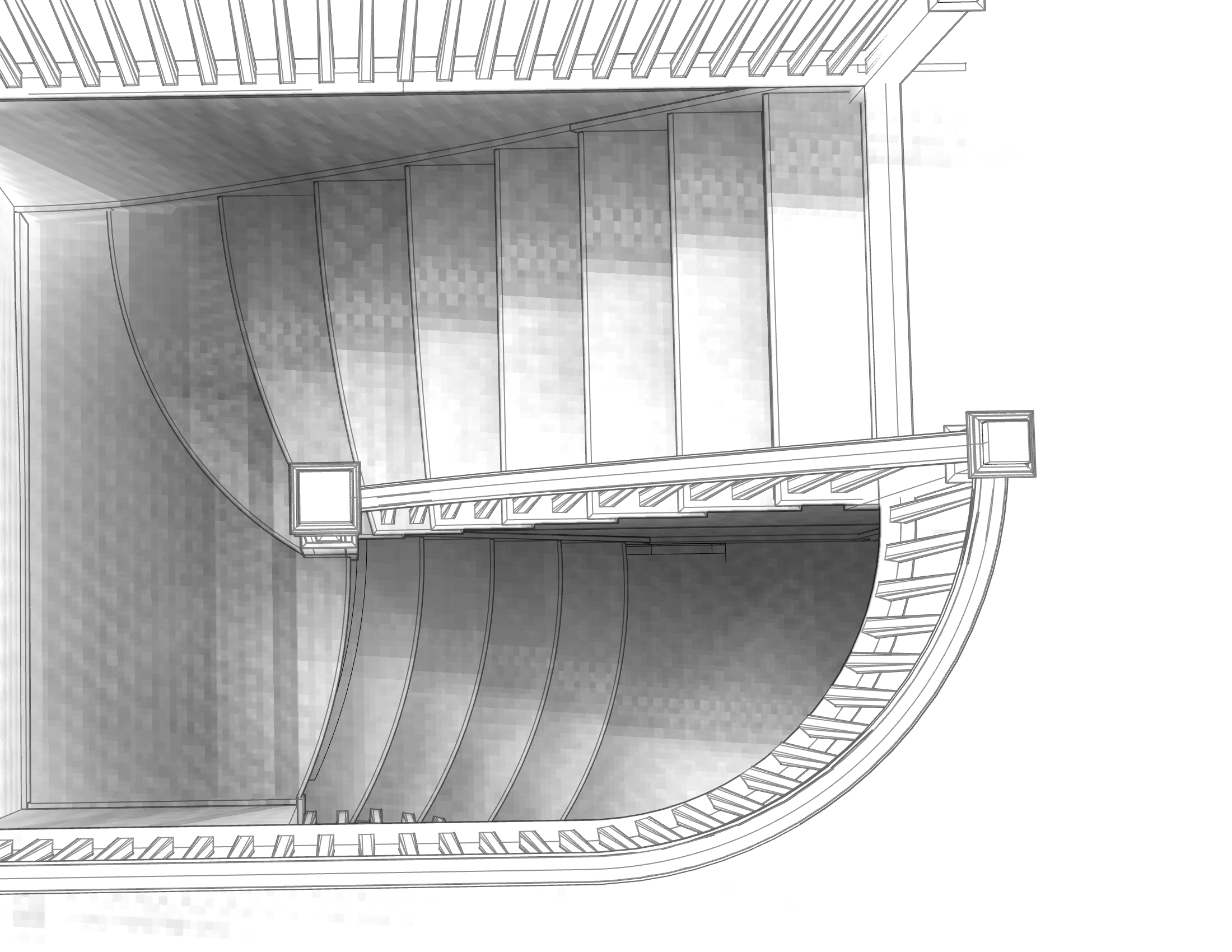

The craft of stairbuilding has changed since the so called "golden years". Standardization and manufacturing have produced boxed components that the average homeowner can afford, and if done skillfully, they can really make a home special and add to its value. However, there are many who know the difference between custom and standard and are not afraid of the investment. This is where I hope to be able to contribute in keeping the stair design and balustrade up to the old classic glory and explore new designs in keeping with the rest of the modern home.